In an oil circuit breaker or OCB, the separating contacts of the breaker are made to separate within an insulating oil because insulating oil has better insulating properties than air.

Oil Circuit Breaker Working Principle

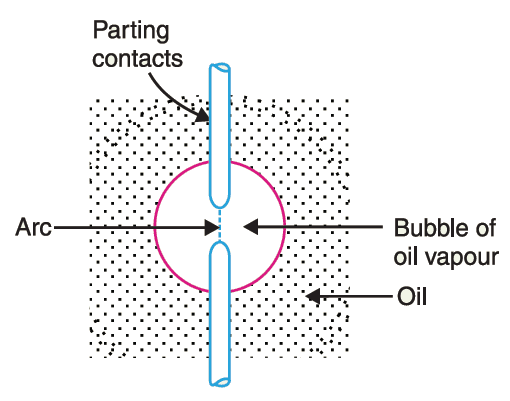

When a fault occurs, the breaker contacts open in oil, an arc is struck between them. Due to the heat of arc, the surrounding oil of the contacts evaporates, and hydrogen gas is produced at high pressure. The oil is pushed away from the arc, and a hydrogen gas bubble surrounds the arc region and adjacent portion of contacts.

Two processes extinguish the arc. Firstly, the hydrogen gas cools the arc due to its high heat conductivity. Secondly, the gas sets up a violent movement in oil and forces it into the space between the contacts.

Thus arcing products are eliminated from the arc path, and arc interruption takes place when the arc current goes to zero, as a result of which arc is extinguished, and circuit current is interrupted.

Following are the main two types of oil circuit breakers:

- Bulk oil circuit breakers

- Low oil circuit breakers

Bulk Oil Circuit Breakers

In these types of oil circuit breakers, a large quantity of oil is used. These are also known as dead tank type oil circuit breakers because the tank is held at ground potential. These can be further divided into:

- Plain Break Oil Circuit Breakers

- Arc Control Oil Circuit Breakers

Plain Break Oil Circuit Breakers

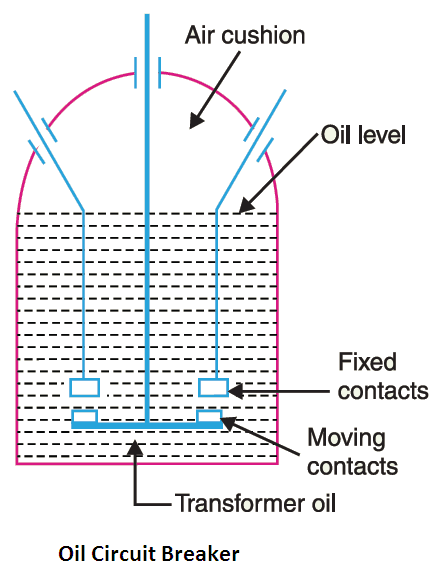

Construction of a plain break oil circuit breaker is very simple. It consists of current-carrying contacts immersed in transformer oil and enclosed in a strong earthed metal tank.The oil acts as an insulator between live parts and earthed tank as well as arc extinguishing medium.

The oil tank is not fully filled with oil, but some space is left for air at the top. Air serves as a cushion and provides space for the displaced oil on the formation of gas around the arc. It also absorbs the mechanical shock produced due to the upward movement of oil.

The breaker tank is tightly bolted to a foundation to bear out vibrations produced at the time of operation of the circuit breaker.

A sufficient head of oil above the arcing contacts is necessary to provide enough oil pressure at the arc and to prevent the occurrence of the chimney effect.

A chimney of gas from the arc to the oil surface is produced. It comes in contact with the earthed tank. If this gas is of low dielectric strength, an arc will strike between contacts and earthed tank. It will result in severe consequences.

Hence a sufficient amount of oil should always exist between the live parts and the tank. A gas outlet from the tank is essential, and some form of the vent is made in the tank cover.

The figure shows a double break plain oil circuit breaker construction. It provides two breaks in series. The two breaks in series provide rapid arc lengthening. For successful interruption of fault current, a comparatively long arc length is essential so that the turbulence in the oil produced by the pressures generated by the arc may assist in quenching it.

Usually, the fixed and moving contacts remain closed, and the breaker carries the standard circuit current. When a fault occurs, moving contacts are pushed down by the protective system, and an arc is struck between the contacts, and a large amount of heat is produced, which vaporizes the surrounding oil into gas. This gas surrounds the arc and displaces the oil violently.

The arc is extinguished when the distance between the fixed and moving contacts reaches a certain value. The speed of the break should be as high as possible because the sooner arc is extinguished, the smaller energy is released in the breaker, and the less mechanically strong a breaker will have to be designed.

The main problem in a double break plain oil circuit breaker is that unequal voltage distribution across the breaks, which results in unequal sharing of the total interrupting duty. Following are the main features that have an essential effect on the performance of plain break circuit breaker:

- critical length of the break,

- the speed of contact movement,

- head of oil above contacts, it depends on the operating voltage of the breaker,

- the clearance between the live parts and the earthed tank.

Among the factors mentioned above, the rupturing capacity of the plain break circuit breaker mainly depends upon the head of oil and large clearances. That is why a large rupturing capacity requires large circuit breakers.

These circuit breakers have become obsolete now. The plain oil circuit breakers were widely employed on low voltage AC and DC circuits up to 250 MVA at 11 kV.

Arc Control Oil Circuit Breakers

In the case of plain break oil circuit breakers, the arc is controlled only by increasing the length of the arc. However, it is required that final arc extinction should occur at a small contact gap too. For this purpose, some arc control is to be provided in the circuit breaker.

The circuit breakers provided with arc control is known as arc control circuit breakers. These are of two types, namely:

- Self Blast Oil Circuit Breaker

- Forced Blast Oil Circuit Breaker

Self Blast Oil Circuit Breaker

In such circuit breakers, the pressure developed by the arc increases the movement of oil in the contact space. The high pressure produced by the arc causes an immediate flow of oil into space between contacts after the arc current goes to zero.

It is obtained by surrounding the contacts by a pressure chamber or pot. The pressure developed by the oil depends upon the value of the current to be interrupted. Such circuit breakers have the following advantages:

- the pressure chamber is relatively cheap to make,

- length for the critical gap is reduced,

- arcing time is reduced,

- the breaking capacity of the circuit breaker is increased.

The major drawback of the self-blast oil circuit breaker is that:

- its arcing time is long,

- poor performance with fault currents considerably less than rated current.

It is due to reduced generation of gas at low fault currents. This problem is eliminated in forced blast oil circuit breakers in which the external mechanical system develops pressure.

In these circuit breakers, the pressure developed is independent of the fault currents to be interrupted.

Forced Blast Oil Circuit Breaker

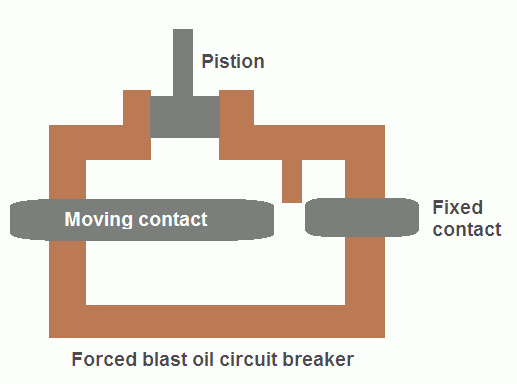

In forced blast oil circuit breakers, the oil pressure is created mechanically by the piston-cylinder arrangement. The movement of the piston is mechanically coupled to the moving contact. Thus when the circuit breaker operates, oil pressure is generated automatically, and the arc is interrupted at high speed.

At low currents, the performance of such a breaker is more consistent than the self-blast oil circuit breaker since oil pressure is independent of fault current.

One more advantage of this design over the self-blast oil circuit breaker is that the quantity of oil required is reduced to one-quarter.

Thanks for reading about “oil circuit breaker construction” and “oil circuit breaker working principle.” For more details, visit Wikipedia.