Hi friends,

In this article, I am explaining the vacuum circuit breaker working principle and construction, and hoping you would like my article.

The high vacuum has a high dielectric strength, and the current interruption in the high vacuum occurs at the first current zero. These two properties of high vacuum make the vacuum circuit breakers more efficient, less bulky, and cheaper.

VCB | Vacuum Circuit Breaker Working Principle

In this type of breaker, the contacts are drawn apart in a chamber from which air has been evacuated.

We know that during contact separation arc is formed due to the ionization of particles in the medium between the contacts. The electric arc is essentially an electric conductor made up of ionized air. Thus, if there is no air, theoretically the arc cannot form. In the vacuum circuit breakers, this medium between the contacts is eliminated.

In practice, however, a perfect vacuum is not likely to be obtained. The small residual amount of air that may exist permits only a small arc to be formed and one of only a very short duration. The same vacuum, however, will not dissipate the heat generated as readily as other insulating media.

A medium that has a pressure below atmospheric pressure (i.e. 760 mm of Hg) is known as the vacuum and the pressures below about 10-5 torr

(1 torr = 1mm of Hg) is considered as the high vacuum. The gas pressures from 10-4 to 10-6 torr are used to serve the purpose of insulation in vacuum circuit breakers. At such pressures of gas, breakdown voltage becomes independent of pressure.

Construction of Vacuum Circuit Breaker

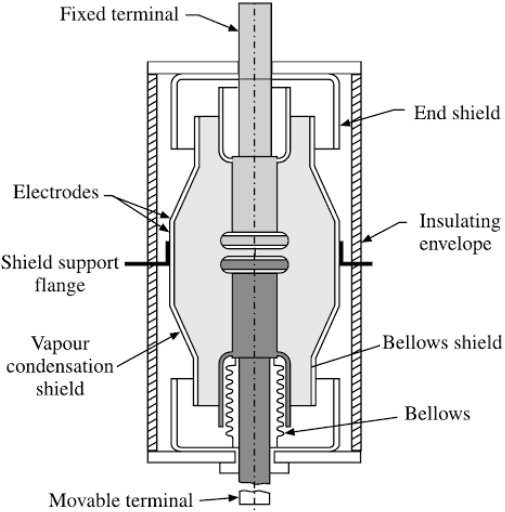

It has a very simple construction in comparison to an air circuit breaker or oil circuit breaker. In a vacuum circuit breaker (VCB) current carrying contacts are separated in the vacuum. The separation of contacts and interruption of arc occurs in a vacuum chamber in the VCB, which is known as the vacuum interrupter.

The outer envelope of the vacuum interrupter is normally made of glass because the glass envelope facilitates the examination of the breaker from the outside. A sputter shield, usually made of stainless steel is placed between the contacts and the envelope to prevent the metal vapors from reaching the envelope because it reduces the breakdown strength between contacts.

Inside the sputter shield, VCB has one fixed and one moving contact. The distance between contacts is kept between 5 to 10 mm depending upon the operating voltage.

The metallic bellows made of stainless steel are used for moving the lower contact. Copper-bismuth, copper-lead, and copper-chromium are some of the alloys used as contact material.

The lower end of the breaker is fixed to a spring-operated or solenoid-operated mechanism so that the metallic bellows inside the vacuum interrupter chamber can be moved upward and downward during closing and opening operations respectively.

In other circuit breakers arc is formed due to the ionization of particles in the medium between the contacts. But a vacuum arc is formed by evaporating its surface material and continues until the next current zero instant.

At the current zero instant, the arc is quenched, and contact metal vapors are condensed again on the contact surface. Due to the high dielectric strength of the vacuum, the vacuum arc can be quenched within a very small contact gap.

The current must be interrupted at zero current instant; otherwise, high voltage transients will be induced due to current chopping. Therefore, for successful arc interruption, it should be stable before the current zero instant.

The arc stability depends upon the contact material very much. Thus arc extinction process in a VCB is related to the material and shape of the contacts and the method used in condensing the metal vapor. The contact surface is so designed that the arc root keeps on moving so that temperature at one point on the contact does not attain a very high value.

Advantages of Vacuum Circuit Breakers

- Current interruption takes place at the first current zero after contact separation with no restriking makes it very suitable for capacitor and cable switching.

- They are pollution-free, non-explosive, and silent operation.

- They provide a large number of operations on load or short circuits.

- Suitable for repeated operating duty.

- They can interrupt any fault current.

- No fire hazards.

- No generation of gas during or after the operation.

- They have a long life and maintenance requirement is minimal.

- They require less power for control operation.

Disadvantages of Vacuum Circuit Breakers

Although this type of breaker has certain advantages in terms of its size and simplicity, its interrupting ratings are not comparable to those of oil circuit breakers. Furthermore, maintenance procedures are more complex and, hence, more costly.

- High-tech plants are required for production, and their production is economical only on a large scale.

- The rated voltage of a single interrupter is limited to about 36kv. If we want to use the VCB at more than this voltage, then we have to use more vacuum interrupters in series accordingly. Thus it becomes uneconomical for a rated voltage of more than 36kv.

Applications of Vacuum Circuit Breakers

- Due to the short gap and excellent recovery characteristics, these are very suitable for high-speed switching industrial applications.

- For low fault interrupting capacities, the cost of VCB is comparatively lower than the other interrupting devices.

- Very suitable and economical for medium voltage range. These are generally used at voltage levels up to 72 kV. Above this voltage, it becomes very expensive to use them.

- Due to the least requirements of maintenance, these breakers are very suitable for rural areas.

Thanks for reading about “vacuum circuit breaker working principle and construction”. For more details, visit Wikipedia.