The induction heating works on the transformer principle. It is also known as eddy current heating. In these machines, the currents are induced by the principle of electromagnetic induction. It may be of low frequency as in the case of core type induction furnaces or of high frequency as in the case of coreless induction furnaces. An alternating magnetic field is set up in the metal to be heated, eddy currents are induced in the metal and heat is produced in it.

The eddy current loss,

We α (B2maxf2)/ρ watts/m3,

Where, Bmax = maximum flux density; f = supply frequency; ρ = resistivity of the metal piece.

Since the eddy current loss is proportional to the product of the square of supply frequency and square of flux density, therefore by controlling the flux density and supply frequency, the amount of heat can be controlled. The frequency may vary from 50 Hz to 8 MHz depending upon the type of work done. High-frequency eddy current heating is frequently used for forging and annealing.

There are two types of induction heating:

- Direct Induction Heating.

- Indirect Induction Heating.

Direct induction heating: In direct induction heating, the eddy currents are produced within the material itself that is to be heated. Examples of direct induction heating are the high-frequency eddy current heating used for case hardening or tempering of various machine parts, annealing of steel strips, and soldering.

The core type induction furnace is used for melting non-ferrous metals such as copper, zinc, and brass. The coreless induction furnace used for preparing various high-grade steels also works on the same principle.

Indirect induction heating: An example of indirect induction heating is the indirect induction oven, which is preferred over a resistance oven due to its excellent temperature control. It is used for the same purpose as the resistance oven.

Moreover, in the indirect induction heating method, the eddy currents are induced in the heating elements by electromagnetic induction, which produces heat in the heating elements. The heat thus generated is transferred to the body to be heated by radiation.

There are two types of induction furnaces. These are:-

- Core type induction furnace.

- Coreless induction furnace.

Core Type Induction Furnace

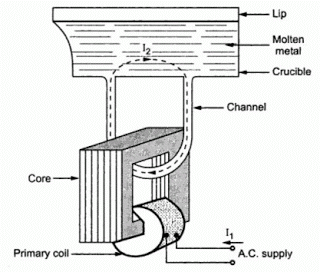

The figure shows a core type induction furnace. It is essentially a transformer with the charge of metal to be heated as single turn short-circuited secondary and magnetically coupled to the primary winding by the iron core.

The current flowing through the charge is very high may be of the order of several thousand amperes. From the figure, it is clear that the coupling is loose, and leakage reactance is high; hence the power factor is low. The furnace is operated at a very low frequency (say 10 Hz) to overcome this difficulty.

The main disadvantage is that electromagnetic forces produce high turbulence of the molten metal, which is useful up to a certain point, but it becomes too severe unless the frequency is kept low. Another disadvantage of this furnace is that a crucible is of inconvenient shape from the metallurgical point of view.

At the time of starting, a complete ring of metal must be present in the crucible; otherwise, the secondary circuit will remain open, and the furnace will not produce heat.

Yet another disadvantage is that it requires a low frequency (10 Hz) supply, which requires a frequency changer, which involves extra cost. On account of the above drawbacks mentioned above, the core type induction furnaces have been obsolete nowadays.

Ajax Wyatt Furnace

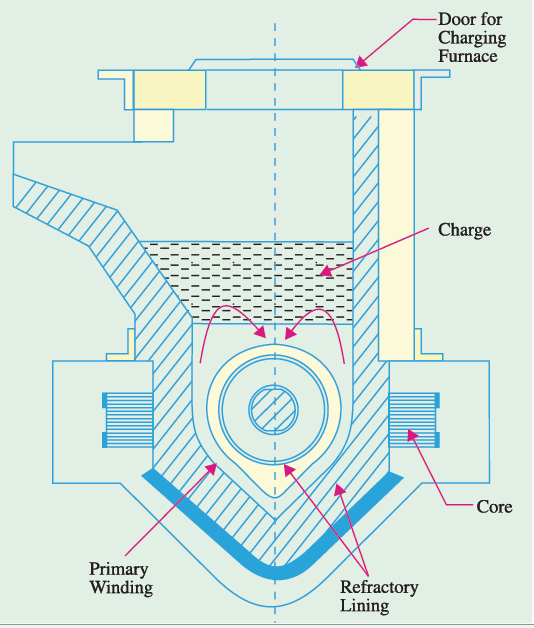

An improved form of core type induction furnace is Ajax Wyatt furnace. This furnace is very suitable for continuous operation, and it can be operated on standard supply frequency i.e., 50 Hz. The core is made of laminated steel, and a single turn of molten metal forms the secondary circuit.

The charge is given from above, and the molten metal is taken out through the spout. The stirring action is produced by the pinch effect, which is proportional to the square of amp-turns. The secondary circuit is only complete when there is sufficient molten metal in the ‘V’ to complete the secondary circuit.

In case the furnace is to be kept overnight without operation, a reduced voltage is applied, which supplies just enough energy to keep the metal in ‘V’ in the molten state.

Applications of Ajax Wyatt furnace: Therefore, Ajax Wyatt vertical core type induction furnace is very suitable for continuous operation. A proper arrangement is made for fitting the furnace to take out molten metal. The power factor of the circuit is about 0.8, and the power required for the furnace to complete melt in a reasonable time is about 200 KW per ton. The melt is completed in about 1 to 2 hours for large sizes and in lesser time for smaller sizes.

Ajax Wyatt Furnace is used for melting and refining non-ferrous metals like brass, copper, and zinc. Its efficiency is about 75 percent. Standard sizes of these furnaces are 60 — 300 KW, single phase 50 Hz working at 600 volts.

The advantages of Ajax Wyatt furnace are as under:-

- Control is simple.

- It provides an ideal working conditions in a cool atmosphere with no dirt, noise, or smoke.

- High power factor 0.8 to 0.85 comparatively

- Absence of the crucible.

- The uniform stirring of charge gives a homogeneous composition.

Coreless Induction Furnace

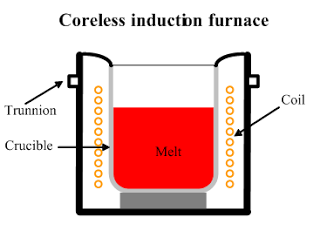

No core is provided in the coreless induction furnace. In this case, also the charge to be melted is made secondary of the transformer. The primary is wound over the crucible itself. The eddy currents produced in the charge not only heat it up but also account for the stirring action. It is the basic coreless induction furnace working principle.

Iron laminations are provided outside the primary winding to create a low reluctance path for flux and also contain the stray field, which may otherwise induce the heavy current in the supporting steel structure.

The frequency employed depends upon the size of the coreless induction furnace. For a low-capacity furnace, a high frequency of the order of 3000 Hz is employed. Whereas for a high-capacity furnace, frequencies are down to 600 Hz. Hollow copper tubes are used in which cold water is circulated to reduce copper losses.

The operating power factor of such furnaces is very low (between 0.1 and 0.3). Therefore, static capacitors are used to improve the power factor of the installation.

Since the power factor does not remain constant during the operation of the furnace, the capacitance in the circuit during the heat cycle is varied to maintain the power factor approximately unity.

The coreless induction furnace is chiefly used for the melting of steel and other ferrous metals. The capacities available vary from 50 Kg to about 20 tons. The initial cost is more as compared to the arc furnace.

The advantages of coreless induction furnaces are as under:

- Low operating costs,

- an automatic stirring action produced by eddy currents,

- low erection loss,

- absence of dirt, smoke noise, etc.

- less melting time,

- simple charging and pouring, precise control of power,

- most suitable for the production of high-grade alloy steels.

Power supply for coreless induction furnaces: For coreless induction furnaces, the power supply is obtained from the ordinary supply system, and its frequency is converted to a higher value using oscillators. These oscillators can generate a very high frequency in the order of megahertz.

The AC supply is stepped up by a transformer and then rectified by using a bridge rectifier circuit. The rectified voltage is applied to the oscillator, and high-frequency output is fed to the charge to be heated through an output transformer.