In the electric arc furnace, the heat is generated by an electric arc. In this furnace, the arc may be created by the following different ways:

1. By striking the arc between the charge and electrode: In this method, the heat is directly conducted and taken by the charge. The furnace operating on this principle is known as direct arc furnace. These furnaces are used for production and refining of various grades of steel.

2. By striking the arc between two electrodes: In this method, the heat is transferred to the charge by radiations. The furnace operating on this principle is known as indirect arc furnace. These are used for the melting of non-ferrous metals such as brass, copper, and zinc.

There are two types of arc furnaces, namely:

- Direct Electric Arc Furnace

- Indirect Electric Arc Furnace

Direct Electric Arc Furnace Working

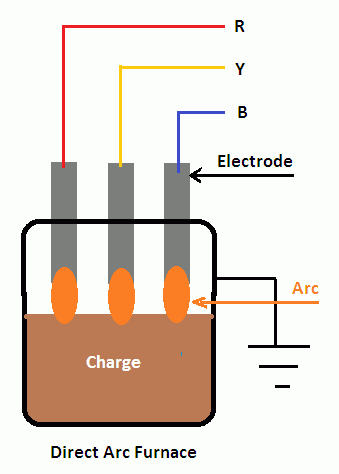

The diagram shows a direct electric arc furnace. The chamber of the furnace is lined with refractory material. The arc is struck between the electrode and the charge. Three electrodes made of carbon or graphite are projected from the top of the furnace, and three-phase supply is given.

The current passes through them via the charge. Since the arc is in direct contact with the charge, so it is possible to produce the highest temperatures by direct electric arc furnace. As the arc passes through the charge, it will produce automatic stirring action.

The arc has a negative resistance characteristic i.e.; resistance falls with the increase in temperature. Thus some current limiting device is required in the circuit to prevent short circuits. It may be in the form of a reactor. The direct arc furnace is very commonly used for the production of steel.

There is a charging door from where the charge is supplied. And also there is an outlet for molten metal. The usual size of the direct electric arc furnace is 5 to 10 tons capacity. For melting 1 ton of steel, 1000 units of energy are consumed.

Indirect Arc Furnace Working

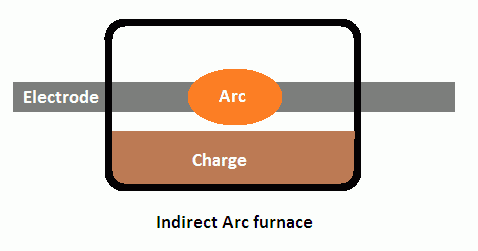

The figure shows an indirect arc furnace. In this furnace, the arc is formed between the two electrodes. And heat so produced is transmitted to the charge by radiation. The temperature is lower than the direct arc furnace. So indirect arc furnaces are suitable for melting metals having lower melting points e.g., non-ferrous metals such as brass, copper, zinc, etc.

The arc is struck between the electrodes, so only two electrodes are required. The supply is, therefore, a single phase. Since during the process of heating, the electrodes are consumed, so the feeding of electrodes to the indirect arc furnace is automatic.

The furnace is cylindrical. Since the arc does not come in contact with the charge, so the automatic stirring action, which is present in the direct arc furnace, is absent. The furnace may be equipped with automatic rocking equipment. The power factor varies from 0.7 to 0.8. The electrode material and electrical equipment of indirect-arc furnace are similar to that used for direct arc furnace.

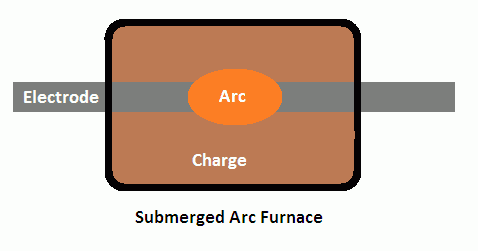

Submerged Arc Furnace Working

This furnace is used for the manufacture of ferrochrome and ferromanganese. In submerged arc furnace, the electrodes project down into the charge remains immersed in it, as shown in the diagram. The power factor is about 0.8.

The heat is produced due to the resistance offered by the charge to the flow of current. Moreover, power is controlled by varying the distance between electrodes or by varying applied voltage to the electrodes.

Power Supply for Electric Arc Furnace

The power consumption of the arc furnaces is very high. The arc voltage is low i.e., between 50-150 V, but the current requirement is of the order of several hundred amperes. As the heating effect is proportional to the square of the current; therefore, a high current is essential to achieve high temperatures. A 3-phase arc furnace transformer is used to obtain the required power supply.

Thanks for reading about the “electric arc furnace working principle”. For more information visit Wikipedia.

Thank you for the detailed explanation of electric arc furnaces and their operations! Understanding the differences between direct and indirect arc furnaces, as well as their specific applications, is incredibly helpful. Your breakdown of how each type works and their ideal uses for different metals provides valuable insights for anyone in the industry. Appreciate the informative and concise overview!

Absolutely! “I’m truly grateful for the advancements in Electric Arc Furnace and arc heating technologies. Their efficiency and precision not only enhance steel production but also contribute to more sustainable manufacturing practices. It’s incredible how these innovations are shaping the future of metallurgy!”

We are very thankful to our readers.

Thank you for this well-structured and informative article on electric arc furnaces! The detailed explanation of direct, indirect, and submerged arc furnaces, along with their working principles, provides great insight into their applications. The inclusion of power supply considerations is especially helpful. Appreciate the valuable knowledge shared in this piece!

This article provides a clear and detailed explanation of the working principles of both direct and indirect electric arc furnaces. It’s insightful to learn how each furnace type generates heat differently and their respective applications in producing steel and melting non-ferrous metals. Thanks for sharing this informative breakdown!

This article provides a clear and detailed explanation of electric arc furnaces, their types, and working principles. The comparison between direct, indirect, and submerged arc furnaces is particularly helpful for understanding their applications. The inclusion of power supply requirements adds further depth. Thanks for sharing this informative piece!

Great article! The utilization of electrical energy in Electric Arc Furnaces and Arc Heating is highly efficient, as it allows for precise control of temperature and energy consumption. These technologies are crucial in industries like steelmaking and metal processing, reducing emissions and improving productivity.

Thank you for sharing this valuable information about Mass Energy’s heat pump program! It’s great to see efforts being made to provide affordable, energy-efficient heating and cooling solutions. The rebates and incentives make it even more accessible for homeowners. This initiative is a big step toward cleaner energy use. Much appreciated!

Electric arc furnaces play a crucial role in metal production, offering efficient heating methods for steel and non-ferrous metals. The distinction between direct, indirect, and submerged arc furnaces highlights their diverse applications. Understanding their power requirements and working principles is essential for optimizing performance. Thanks for this insightful explanation!

This is a clear and informative explanation of arc furnace types and their working principles. The comparison between direct and indirect arc furnaces is especially helpful for understanding industrial applications. Thanks for highlighting the practical uses and technical differences so clearly—very useful for students and professionals alike!