The procedure of connecting an alternator in parallel with another or with common bus bars is called synchronization of alternator.

Conditions for Synchronization of Alternators

For proper synchronization of alternator, the following conditions must be fulfilled:

- The terminal voltage of the incoming alternator must be equal to that of the bus bars voltage.

- The speed of the incoming alternator must be such that its frequency is equal to that of bus bars.

- The phase sequence of incoming alternator must be the same as that of bus bars.

All these conditions must be full filled to ensure that there will be no circulating current between the windings of the alternator already connected to the bus bars and the incoming alternator.

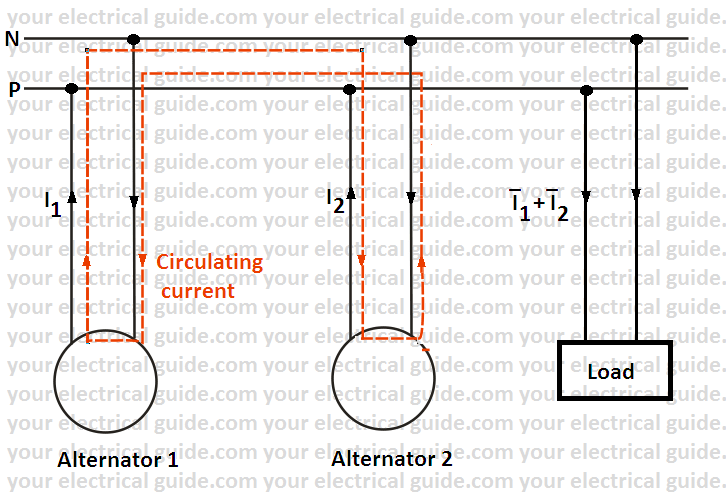

To understand the situation that will come across if the above conditions are not achieved, consider only two single-phase alternators connected to the common bus bar operating in parallel, as shown in Figure.

When a load is connected to the bus bars, there are two circuits to which the alternators can supply current. One circuit is the external load, and the other is the local internal circuit, i.e. synchronous impedance of the two alternators.

If above mentioned conditions are not full-filled, a current (circulating current) will flow through the local internal circuit of alternators. This circulating current will load two alternators, without supplying any power to the external load. If too high circulating current flows, it may damage the alternators.

Methods of Synchronization of Alternator

Here I am describing the ‘two bright and one dark lamp method’ of synchronization of alternators. This method is generally used in colleges to demonstrate this process to students.

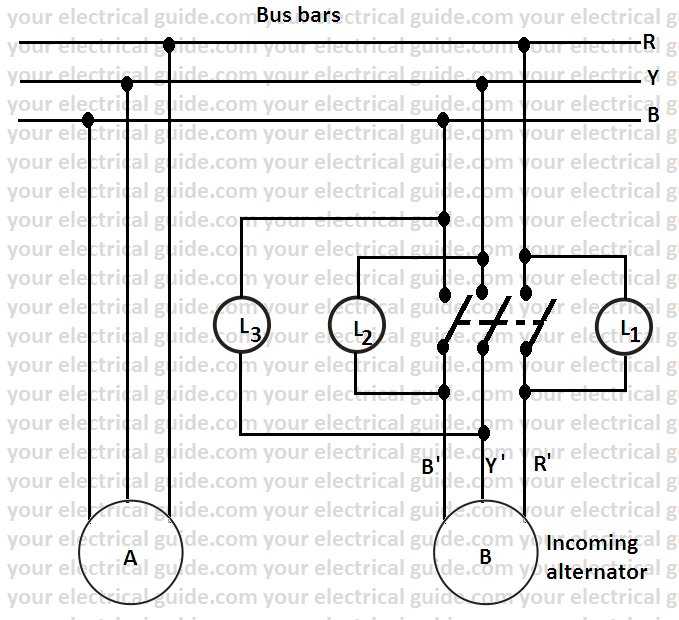

Consider an alternator B is to be synchronized. In this case lamp L1 is connected across R – R’, lamp L2 is connected across Y – B’ and lamp L3 is connected across B – Y’ as shown in Figure.

If the voltages are equal, the frequencies are identical, and the phase sequence is correct then the voltage across L1 will be zero and across L2 and L3 will be line voltage.

Under this condition, the lamp L1 will be completely dark, and the lamp L2 and L3 will be equally bright. This is the ideal condition for closing the synchronizing switch.

When the frequency of the incoming alternator is different from that of bus bar frequency and the remaining conditions are fulfilled, then the three lamps will flicker alternatively (i.e. one after the other in sequence).

The flickering of the lamps will indicate the difference in speed of the incoming alternator. Accordingly, the speed is adjusted to minimize the flickering of the lamps.

However, if the phase sequence is not correct, all the three lamps will flicker in unison. Then the phase sequence should be corrected by interchanging any two leads of the incoming alternator at the synchronizing switch.

If the voltage of the incoming alternator is not equal to that of bus bar voltages and the other conditions are satisfied, all the lamps will glow with different brightness and will continue to attain the same brightness. The ideal condition can be achieved by adjusting the excitation of the incoming alternator.

Thus when the flickering frequency is minimized, lamp L1 is dark, and L2 and L3 are equally bright, the synchronizing switch should be closed.

This method is only suitable for small low voltage alternators. For large capacity, high voltage alternators, a synchroscope is almost invariably used for synchronizing.

Synchronizing of Alternator by Synchroscope

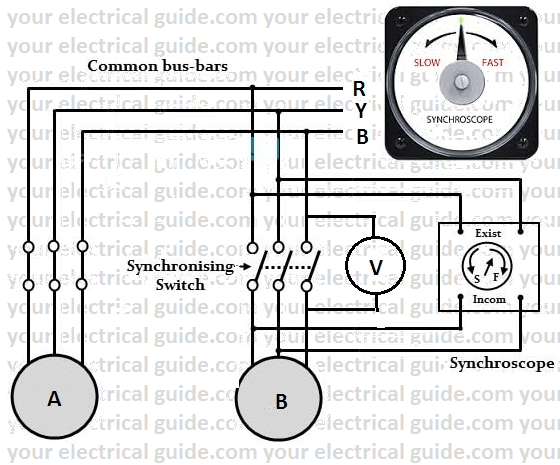

Synchroscope is an instrument used for synchronization of alternators. It indicates whether the incoming machine is running fast or slow. To do the synchronization of alternators by this device,

1. Connect the alternator, synchroscope and other devices as shown in the above Figure.

2. Check the phase sequence of the incoming machine with the help of a sequence indicator or small induction motor.

To determine the phase sequence with the help of induction motor, connect a small induction motor with bus bars and incoming alternator one by one. If the induction motor is running in the same direction in both cases, then the phase sequence is the same.

Interchange any two phases of the incoming alternator at the synchronizing switch if it is not correct.

3. By adjusting the speed of the incoming machine, make the pointer of synchroscope stationery in the vertical position.

4. Measure the voltage of incoming alternator, make it equal to that of the bus bars by adjusting the excitation of the incoming alternator.

5. After satisfying all these conditions, the voltmeter will show zero reading. Now close the synchronization switch.

Shifting of Load on Alternators

After closing the synchronizing switch, alternator B is connected in parallel with the alternator A. At this instant alternator B is not delivering any load (current) to the bus bars.

The load is shifted from the running alternator A to the incoming alternator by increasing the mechanical power input to the prime-mover of alternator B and simultaneously reducing the mechanical power input to the prime-mover of alternator A.

In case of steam machines, this can be readily done by opening the steam valve of the alternator B and simultaneously closing the steam valve of alternator A.

Thus any load can be shifted to incoming alternator B from alternator A. Generally it is shifted as per their respective ratings.

If alternator A is to be disconnected from the bus bars, the process continues till the whole of the load is shifted to the incoming alternator B as indicated by the ammeters and watt-meters in the line circuits. Then the circuit breaker (main switch) and the field breaker (field switch) of alternator A are opened.

The most important point, to be noted, is that the load cannot be shifted from one machine to the other by adjusting the excitation. Once the alternator is connected to the bus-bars, the change in excitation only changes the power factor of the alternator.

Infinite Bus-bars

The large grid systems which are fed by numerous alternators of very large capacity are termed as Infinite Bus-bars.

Control of bus-bar voltage: When several alternators are running in parallel, the bus-bar voltage can be regulated by regulating the excitation of all the machines. Change of excitation of any one machine will only affect the reactive load delivered by the machine.

Control of bus-bar frequency: When several alternators are running in parallel, the bus-bar frequency can be regulated by regulating the power input to all the machines. An increase of power input to any one machine will merely cause it to take more load at the expense of the other machines with the possibility of damage to itself.

Thanks for reading about the “Method of synchronization of alternators.” For more information, visit Wikipedia.