The second design

3D-PV (Organic)

The first design of 3D- solar organic cells was dependent on the concentration of the sun, we use optical devices such as a parabolic mirror or Fresnel lens to enter the sunlight from a small area (focal point) and retained inside until fully absorbed.

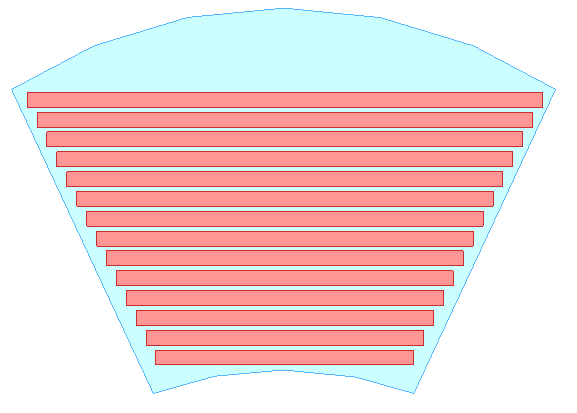

But there is another simple design for 3D-organic solar cell that needs no concentration, we follow the same steps in printing cells and cutting the roller into solar modules (Here the module can only have one cell), use reflective coatings and then cut the edges of the module, As shown in the following figure.

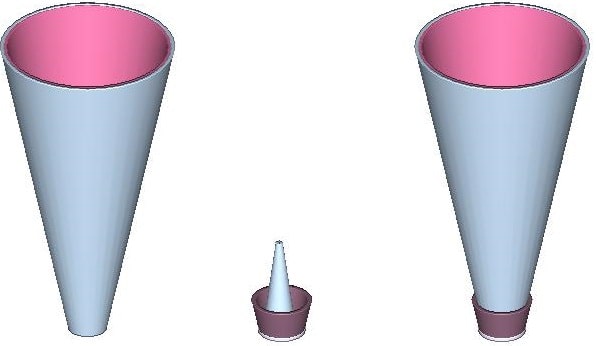

Then the solar module flexes in the form of a cone minus, install the sides by a plastic slide where the surface area of the 3D cell exposed to the sun is the area of the cone base, as shown in the following figure.

We use with conical cell at the end of the lower part, another small cone made of plastic coated from the outside with reflective coating to prevent escape of sun- light reflections from the conical module, as shown in the following figure.

The small cone is easy to jaw and combination with the cone module for the maintenance work of the cell (dust collected in the small corner)

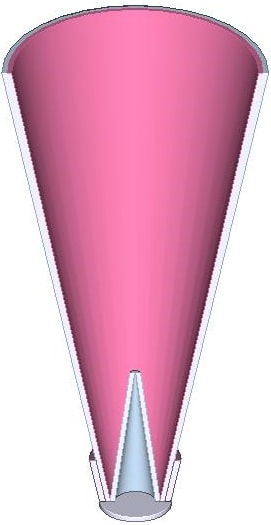

The cone cell achieves efficiency up to 90% while the flat cell is 7% on the same area exposed to the sun but in contrast, the cost of a conical cell is greater than the cost of a flat cell to cover the same area Longitudinal section of the conical cell and cone reflector, it shows reflectivity inside the cell, preferably the angle of the cone head is small because it achieves greater reflections of sunlight within the cone especially in the hours of sunset and sunrise.

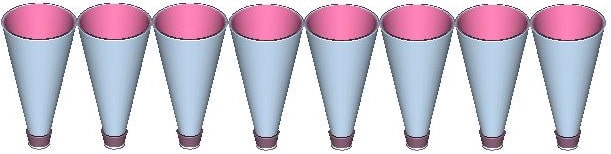

Cone solar cells can be used individually with Different sizes may be very large in the size of canopy or small in the size of the lamp.

We can arrange the cells on the wall of the house or school or next to each other to build a 3D solar panel, can be fixed do not track the sun or can be moving in tracking system on two axes and in this case the angle of cone head it will be large and therefore cost less.

The third design

3D-PV(Organic)

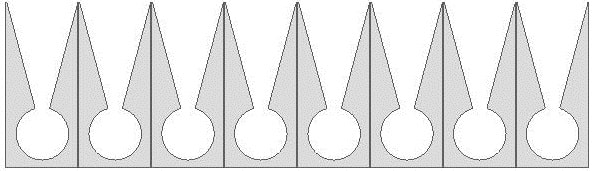

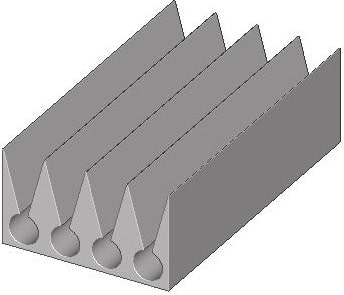

The third design of 3D- organic solar cells it is more effective and less expensive than the previous design, follow the same previous steps to print the cells on the roller, cut the roller into solar modules and use reflective coatings. This design is based on a set of molds have a 3D shape, made of plastic, as shown in the following figure.

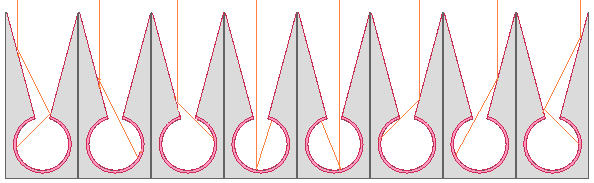

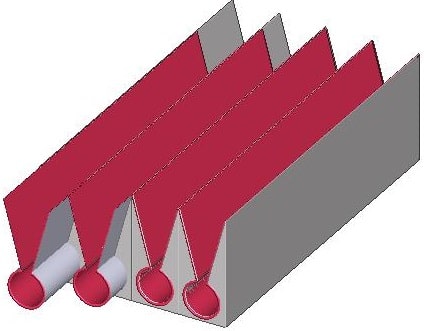

Each solar module is placed inside the mold, the module is pasted on the inner wall of the mold, so take the same mold shape from the inside. The solar module and the cells also become in the 3D mode as shown in the following figure, See also reflectivity within the cell from vertical beam.

Arrange the molds containing the solar modules in an array to construct a three-dimensional solar panel, they are bonded together by an outer plastic frame and a panel of anti-reflective glass is placed on top of the 3D solar panel, to prevent soil penetration into the 3D cells.

The second design can work without the need for a tracking system but the third design needs a tracking system on two axes, to absorb all reflections of sunlight where the beam falls on it vertical.

But it is more effective because there are no breaks between the molds or 3D solar modules as in the second design, and it uses the solar modules with small space and this saves the cost also.