Power transformers are critical and costly assets in the electric power system. They are one of the most important electric apparatuses for providing reliable energy flow. They also constitute one of the largest investments in a utility system or in an industrial complex. For this reason, transformer condition assessment and management are a high priority. And therefore, online monitoring of transformers has become very essential.

Each entity is unique and investment levels in asset condition and assessment management vary according to risk level and investment return models. While the models are different for each entity, the common element in them is that transformers are stratified according to the criticality of individual transformers.

The variability and uniqueness lie in where the prioritization lines are drawn and the investment amounts allocated for condition monitoring for each level. Typically this approach has the most critical transformers receiving the highest investment of condition assessment and management tools and less-critical or noncritical transformers receiving a decreasing level of asset allocations. A simplified model below shows one approach to transformer condition management:

Critical: Those transformers that, if failed, would have a large negative impact on grid stability, utility revenue, and service reliability of the critical facility. For example, generator step-up transformers (GSU) and transmission transformers that are part of critical power flow fall in this level, or the main transformers in a critical facility.

Important: Those transformers that, if failed, would have a significant negative impact on revenue and service reliability of a utility system, or the production of the plant. Transmission substation transformers and major distribution substation transformers are generally at this level.

Recoverable: Those transformers that, if failed, would have a low impact on revenue and reliability or the production of the plant. These are mainly smaller distribution substation transformers.

Transformer reliability is more important today than was in the past. Utility and plant managers by choosing the appropriate transformer condition monitoring tools can avoid unplanned failures, lower maintenance costs, and defer capital expenditures in replacement cost. Condition management is all about choosing the right monitoring tools for transformers.

Online Monitoring of Transformers

There are several online monitoring systems that can be used for continuously assessing the condition of large important and critical power transformers. The online monitoring systems that are available on the market are DGA, PF monitoring of bushing, leakage current monitoring of lightning arrestors, and FRA of transformer windings.

The bushing and lightning arrestors are externally mounted auxiliaries on a transformer therefore they are more susceptible to varying environmental conditions. A failure in the bushing or lightning arrestor of a transformer is a failure of the transformer.

Online testing offers yet another management tool for condition monitoring and assessment of the most critical and important transformers.

The dissolved gas analysis (DGA) of transformer oil is one of the many tests that are used in monitoring the health of oil-filled power transformers. The off-line DGA tests have been traditionally carried out using laboratory DGA analysis performed at periodic intervals, such as on a quarterly, semiannually, or yearly basis. DGA of transformer oil is the single best indicator of the overall condition of the transformer and is carried out without taking it out of service. This is a universal practice today that began in the 1960s.

While laboratory or portable DGA is the traditional practice, the use of online DGA tools has gained in popularity. The reason for this is the need for utilities to maintain or improve their reliability. DGA is needed to be successful in the current environment and the two approaches (online DGA and laboratory DGA) now coexist at many utilities. Online DGA helps utilities avoid unplanned failures and extends the transformer’s useful life.

First-generation products (1970s), as well as some current online DGA products available today, provided total combustible gas (TCG) or single gas (hydrogen) monitoring. These products provide an indication of developing problems in the transformer but offer no legitimate diagnostic capability.

Online DGA offerings in the market have evolved from this early approach to include multigas monitors that detect and analyze some or all of the eight fault gases identified in the IEEE standards as well as provide the diagnostic capability.

Newer online DGA products have the unique ability to continuously trend multiple transformer gases and correlate them with other key parameters such as transformer load, oil, and ambient temperatures as well as customer-specified sensor inputs.

This capability enables utilities to relate gassing to external events, a key to meeting utility reliability and financial goals in the current environment. In fact, some online DGA tools may offer better accuracy and repeatability than laboratory DGA.

This can improve the transformer asset manager’s decision timeliness and confidence when incipient faults are detected. With the advent of online DGA monitoring, there has also been new learning about the nature of developing faults in transformers.

Online DGA monitoring has produced multiple case studies that document the development of critical faults, which could cause catastrophic transformer failure if left undetected, in timeframes from a few days to a few weeks.

There is a low probability of capturing these rapidly developing fault conditions with a laboratory or portable-based transformer DGA testing program. Recently, the ability to automatically supplement traditional DGA diagnostic tests with online DGA tests is available in the market.

This new development offers users of online DGA monitors unprecedented insight into the nature and identification of developing faults. The tools are typically ratio-based and the online data set enables trending of fault gas ratios over time rather than the traditional static snapshots. Diagnostic outcomes can now be determined quickly and with more certainty than in the past.

One of the online tools available for condition monitoring of transformers is the online DGA, such as Siemens Gas Guard 8. The Gas Guard 8 is a self-contained fully automated closed-loop gas chromatograph designed to be mounted on or near the subject transformer.

Through chromatography, the Gas Guard 8 generates individual measurements of each of the eight critical fault gases (hydrogen, nitrogen, carbon monoxide, carbon dioxide, methane, ethane, ethylene, and acetylene) found in transformer oil. The accuracy of the measurements is comparable with what one would expect to receive from a traditional laboratory.

Selecting Online DGA Tools

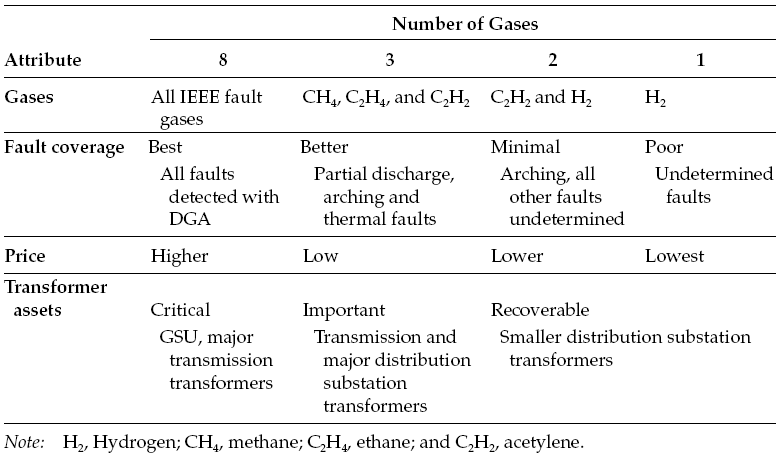

The last few years have seen a new array of DGA tools. Table 1 contains a list of attributes for various online DGA product categories relevant to online DGA tool selection and how it could be applied to the three levels of transformer assets.

Online DGA tools can be categorized by attributes directly resulting from the number of gases measured. Most modern online DGA tools offer the ability to measure other parameters such as moisture-in-oil. These other parameters are not included in the table as they are common for most.

Fault coverage and diagnostics capabilities are the critical attributes that transformer asset managers should consider when choosing online DGA tools for the various levels in their stratification models. Price is also a consideration.

The selection of online DGA tools for each level of transformer assets identified reflects the approach of making the highest investment in online DGA tools for the most critical transformers and less investment in tools for lower levels in the stratification model. Notice that this approach utilizes the online DGA tools with the most fault coverage and diagnostics for the critical and important transformers in the fleet.

Utilities will find more appropriate returns on investment for their critical and important transformers with online DGA tools that offer good fault coverage and diagnostics capability rather than with the lowest cost, poor fault coverage tools that lack diagnostic support.

The current environment of higher loading on aging transformers, deferred capital expenditures as well as increased service reliability requirements suggests that transformer asset managers should take advantage of the improved online DGA offerings (i.e., better fault coverage and diagnostics) in the market to get the best protection for its biggest asset class—at all levels. Appropriate online DGA monitoring and diagnostic tools will help utilities avoid unplanned failures, lower maintenance costs, and extend transformer useful life.

Online Monitoring of Transformer Bushings

Normal aging of HV equipment is a slow process that takes place over 30–40 years due to thermal, electrical, and environmental effects. With regard to transformer bushings, the most common type of bushing failure occurs due to a failure in the internal bushing capacitive layers. These failures occur slowly over time with one layer slowly failing and burning through the kraft paper.

Premature failure on the other hand is often a relatively sudden process that is not detected by periodic off-line tests. The use of the Schering bridge technique using the voltage is very responsive to the type of condition and can detect these millivolt level changes. The millivolt level changes are far too small for an offline test to detect and react to it in the early stages of failure.

This prompted the need for continuous online insulation condition monitoring to manage the risk of premature bushing failures and to initiate maintenance procedures based on the condition of the bushing insulation.

The online monitoring of transformer bushings performs PF (tan δ) testing of transformer bushings and lightning arrestors while the transformer remains energized. The PF calculation in the system is based on the conventional Schering bridge used in laboratories.

Data is acquired under software control from transducers connected to the bushing PF/capacitive tap associated with a transformer and then the data is compared to data from another electrical phase to produce a PF value.

Damaged or deteriorated dielectric is associated with increased dielectric losses with other sources of heating that may eventually fuel a mechanism of thermal runaway. The eventual breakdown of insulation is a rapid avalanche of failing dielectric layers.

PF is a measure of dielectric losses, partial discharges, and treeing. High levels of partial discharge are reflected in the PF and are usually only present just after lightning or switching impulses and just before and during insulation failure.

The National Electric Energy Testing, Research and Application Center (NEETRAC) has developed a method to perform the FRA test while the transformer is in service. Online FRA data can provide an up-to-date condition assessment of large, essential transformers. Online FRA provides yet another tool to analyze the physical structure of the coils and their dielectric surroundings while the transformer remains in service.

Thanks for reading about “online monitoring of transformers”.