A perfect cable can be electrically modeled by a single capacitor. The longer the cable, the larger the capacitance of this capacitor. As the insulation of the cable degrades, losses in this capacitor increase which can be measured by tan delta testing of the cable.

The measurements can be compared with previous test measurements and trended to assess cable health.

Tangent delta testing is independent of the length of the cable, as it is a ratio of resistive losses to capacitive losses (the cable itself).

Cables with poor insulation have higher DF (tan δ) values than normal and will exhibit higher changes in the tangent delta values with changes in applied voltage levels. Good cables have low individual tangent delta values and low changes in tangent delta values with higher applied voltages levels.

PF tests are not very effective in detecting localized faults as the length of the cable under test increases. However, PF tests are useful in indicating general deterioration and contamination of the cable. The hot collar tests are the most effective tests for cable accessories, such as potheads.

Tan Delta Testing of Cable

DF/PF/ tan delta testing of cables requires additional precautions since cables are run in duct banks and conduits or are directly buried in the ground, and are not visible other than the ends of the cable. Therefore both ends of the cable under test should be clearly identified and isolated.

The additional concern involves the ground return path of the current to the test set. Effective PF test can only be performed for the shielded and sheathed cables. It is recommended that the PF test for unshielded or unsheathed cables should only be performed if a definite ground return path can be provided back to the test set.

Also, because of the long lengths of cables (large capacitance), the charging current of these cables may be very large and beyond the capacity of the PF test set. As a result, the PF tests can be performed on relatively short lengths of cables.

The PF tests for cables are divided into shielded and sheathed cables and unshielded and unsheathed cables.

Shielded or Sheathed Cable

The single conductor cable should be de-energized, isolated, and grounded to discharge the cable completely before conducting a PF test on it.

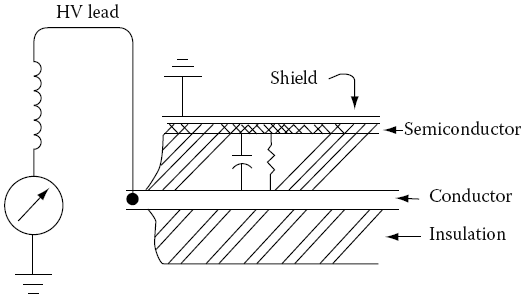

The HV lead of the PF test set is connected to the cable conductor and the cable shield or sheath is effectively grounded as shown in following Figure.

The test is conducted in the GST mode and the voltage of sufficient magnitude (voltage should not exceed the cable’s normal operating voltage) is applied depending upon the voltage rating of the cable.

Multiconductor cables which are individually shielded can be tested similar to the single conductor shielded cables with the other cables not under test effectively grounded.

Unshielded and Unsheathed Cables

The single conductor unshielded or unsheathed cable may be tested similar to the single conductor shielded cable. However, the test results (measurement of the PF) may include PF measurements of other materials surrounding the cable or any materials that form the ground return path of the leakage current.

In other words, the losses in materials that are not part of the insulation are included in the PF measurement, thus giving unpredictably higher PF results.

Also, it is unsafe to conduct the PF test in this manner since the return leakage current path is not exactly known and therefore may pose a danger to the test operator. Therefore this procedure is not recommended.

Instead, if PF tests are to be conducted on such cables then the procedure recommended is to use another phase conductor of the same circuit (or a spare cable if available) as a leakage current return path by connecting the far ends of two cables.

The test is performed in the UST mode to conduct PF test measurement between the two cables. Similarly, multiconductor unshielded or unsheathed cables may be tested in this manner.

Any other cables not included in the test should be effectively grounded. This procedure is repeated to include all conductors in at least one measurement.

In this test, the applied voltage is usually stepped up from below operating voltage to slightly above operating voltage. In practice, a very-low-frequency (VLF) HV test is often used as the voltage excitation source to perform the tangent delta tests. VLF as an energizer source is preferred for two reasons:

- the increased load capability in field applications in which 60 Hz is too bulky and expensive, and

- the increased sensitivity and effectiveness of measuring DF in the low-frequency range for extruded cable.

Since XLPE and some EPR cables have very low tangent delta values when in good condition, the tangent delta resolution of the measurement equipment should be at least 1 × 10−4 to get accurate, meaningful results.

In addition, a guard circuit to drain off surface leakage currents at the terminations should be used to give true tangent delta results during a measurement. This normally requires a VLF test instrument with a virtual ground return, instead of a solidly grounded VLF generator.

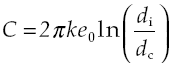

For lossless insulation, the cable capacitance (C) per unit length can be defined by the following equation:

Where k is the dielectric constant of the insulation, e0 is the permittivity (capacitance) of free space (air), di is the diameter over the insulation, dc is the diameter of the conductor, ln is the natural logarithm (log to the base e).

For cable with conventional insulating materials, the cable conductance (G) per unit length can be defined by the following equation:

G=2π fC tan δ

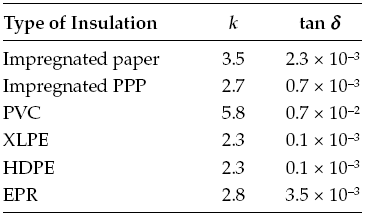

The quantity tan δ gives the losses in the insulation when subjected to an electric field and is known as DF or the loss angle of insulating material. The table below provides typical values of dielectric constant k and tan δ.

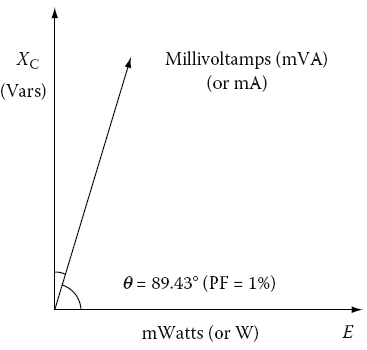

When a voltage V is applied to the loss-free insulation system (dielectric), the total current IT drawn by the dielectric is the sum of the capacitive charging current IC and loss current (resistive) IR.

As shown in above Figure, the angle formed by the current IT and IC is δ, and the angle formed by the IT and voltage E is θ where cos θ is the PF of the dielectric.

The DF (tan δ) test allows an evaluation of an insulation system at operating voltage level and frequency. The tan δ test can also be performed at a frequency other than 60 Hz, such as at VLF of 0.1 Hz during a proof test conducted at such frequency.

According to IEEE std 400-2001, tests conducted on 1500 miles of XLPE insulated cable have established a figure of merit for XLPE at tan δ = 2.2 × 10−3. If the measured tan δ is greater than 2.2 × 10−3, then the cable insulation is degraded by moisture in the form of water trees (voids in the insulation filled with water), and it is recommended that additional hi-pot tests, such as VLF test be conducted to identify the defects in the cable insulation. The tan δ test for each conductor with respect to ground should be made.

Evaluation of Test Result

The overall PF value of a cable is a function of insulation type, length, size, installation (whether it is installed in metallic or nonmetallic conduit), and voltage. Therefore, the evaluation of the field PF test results should be based on comparison with previously recorded tests on the cable when it was put in service and was relatively new, such as during acceptance testing or correlated with test results of similar types of cables.

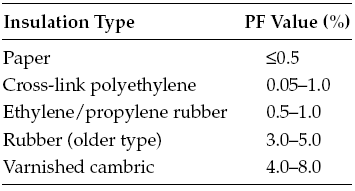

Typical PF values at 20°C for cable insulation system as listed in the Doble Engineering Company reference book are shown in Figure.

It should be noted that cables without a metallic sheath or grounded shield, but are installed in metallic raceway may have PF higher than the values listed above.

The results of the hot-collar tests on potheads are evaluated by comparing field test results on similar types of potheads, or previous years recorded test results. The evaluation is based on watts loss and current, and PF.

Abnormally high dielectric loss and current indicate the presence of moisture. Below than normal test current indicates the absence of compound or oil in the pothead. An increase in watts loss with an increased test voltage (PF tip-up) indicates the presence of corona.

Thanks for reading about “tan delta testing of cable”.