Most insulations fail during one of the following events:

Switching overvoltage due to the inductive and capacitive energy of the system overshooting the system voltage that can be as high as 2 × rated voltage. This is analogous to overpressure due to water hammer when a water pipe is suddenly shut off (switched-off).

Lightning overvoltage of magnitude I × Zo, where I is a fast-rising lightning current wave entering the system via cable with impedance Zo, known by three names—the characteristic impedance, wave impedance, or the surge impedance of the cable. The lightning voltage entering the equipment can vary from 15 kV to 1500 kV and may last for about 100 µs.

When a switching or lightning overvoltage occurs in the system that exceeds the insulation strength, the insulation between two live conductors or between one line and the ground can break down.

The lightning current can enter the equipment via incoming line, resulting in overvoltage that can cause damage, particularly at the line connection end of the equipment.

The generator, transformer, and motor are designed with a certain minimum basic impulse level (BIL) that the equipment can withstand under lightning and switching type transient voltages consistent with the lightning risk. The risk is proportional to the number of thunderstorms per year in the area.

Lightning and Switching Voltage Protection Methods

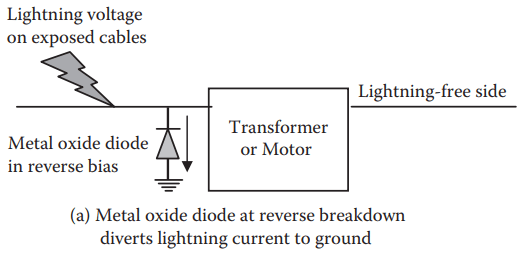

Metal oxide: Electrical equipment can be protected from lightning damage by placing a metal oxide lightning arrester as shown in Figure 1.

Functionally, the arrester works like a diode in reverse, which breaks down at lightning voltages. They are made from lead peroxide or Thyrite® hockey-puck shape pellets stacked with series gaps. It consists of a column of diode type lead peroxide pellets with small series gaps assembled in a porcelain tube placed before the equipment as shown in Figure.

The semiconducting pellet material has highly nonlinear resistance that behaves like a diode in the reverse bias. The series gap isolates the diode elements from the line voltage until sparked over by a lightning impulse that breaks down the reverse biased diodes. Arresters use a zinc oxide and petticoat insulator standoff.

The arrester material does not get damaged after the breakdown. It recovers its normal voltage blocking property once the lightning voltage is diverted to the ground. Therefore, it does not need to be replaced after every lightning strike.

It does, however, wear out after a certain number of lightning hits, and may need to be replaced periodically after several years depending on the type of the material used. The arrester must have proper voltage rating. Too high a rating will not protect the equipment, and too low a rating will cause damage to the arrester itself.

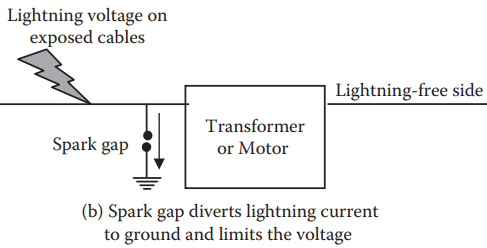

Spark-gap: A spark-gap before the equipment as shown in Figure 2 is another way of providing lightning protection. The air in the spark gap under normal operation keeps the ground current zero, but it breaks down under high lightning voltage, diverting the lightning current to the ground.

The air gap recoversits blocking property once it cools down after a strike, but may need replacement after numerous lightning strikes causing surface erosion.

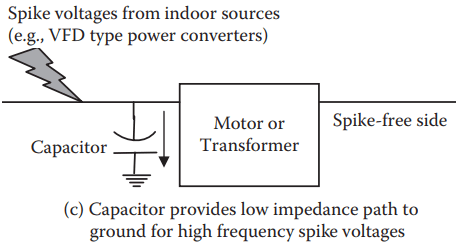

Capacitor: The best protection for electrical equipment can be achieved by a combination of the lightning arrester and the capacitor placed as close as possible to the equipment as shown in Figure 3.

Such a protection scheme is particularly used for motors, where the pf improvements capacitors are also normally used. The lightning voltage that passes onward beyond the lightning arrester reaches the motor and is absorbed by the capacitor.

The low impedance of the capacitor for virtually high frequency lightning voltage smoothes out the steep front part of the voltage surge as it enters the stator winding.

The capacitor’s approximate ratings found satisfactory in most cases are: 1 μF/phase for system voltage 600 V or less, 0.5 μF/phase for 600 < V < 6.6 kV, and 0.25 μF/phase for 6.6 kV to 13 kV systems.

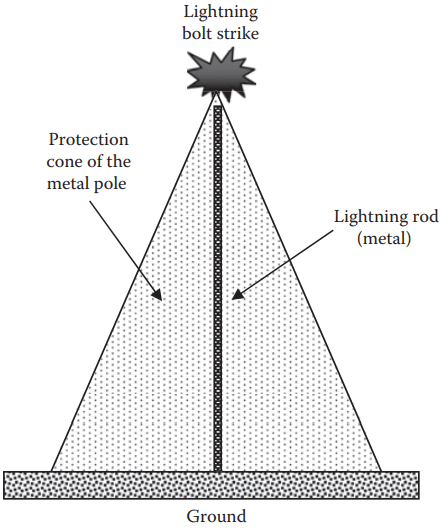

Lightning rod: In addition to the lightning protection outlined above, a tall metal rod is used to create a lightning protection zone around the area to be protected, on buildings, substations, ships etc.

Such a protection zone has a conical volume (Figure 4), starting from the tip of the rod, and extending to the floor radius that depends on the rod height and the polarity of lightning strike.

Surge Protection for Small Sensitive Loads

The surge protector (suppressor) protects small sensitive loads from damaging voltage surges (spikes). The voltage spikes can come from the utility power lines or generated from local sources.

For example, a large fuse-blow event in the neighborhood can generate large voltage spikes along the power lines, damaging the equipment that is plugged into nearby ac outlets.

The surge suppressor protects the connected loads by diverting the voltage spikes to ground through the outlet’s ground wire. For this reason, running a surge suppressor from an ungrounded outlet prevents the surge suppressor from providing such protection.

The surge suppressor is connected in front of the load. It typically contains a diodetype material in the reverse bias to the ground. It blocks the ground current under rated line voltage.

However, if the line voltage exceeds the diode breakdown voltage, it becomes conductive and diverts the voltage spike to the ground. The highest voltage the load equipment would, therefore, see is the reverse break down voltage. The diode is designed to absorb the generated heat in joules without thermal failure. Once cooled down, its heals itself, that is, it recovers the reverse voltage blocking capability.

In commercially available surge suppressors, the key components used to reduce or limit the high voltage spikes may include one or more of the following:

Metal oxide varistor (MOV): This is the most common protection component, which is typically granular zinc oxide that conducts current only under a voltage above itsrated breakdown voltage.

It typically limits (clamps) voltage to about three to four times the normal circuit voltage. It degrades in performance when exposed to repeated spikes, hence has a finite life.

MOVs may be connected in parallel to increase current capability and life expectancy, providing they are matched sets (MOVs have a tolerance of approximately 20% on voltage ratings). MOVs usually are thermal-fused to avoid short circuits and other fire hazards. A failure light indicates a blown thermal fuse on some models. However, even an adequately sized MOV protection eventually degrades beyond acceptable limits without a failure light indication.

Zenar Diode: The zener diode, also known as an avalanche diode, is another clamping semiconductor similar to the MOV. It provides the best limiting action of protective components, but has a lower current capability.

Spike voltage can be limited to less than two times the normal operation voltage. Its life expectancy is long if current impulses remain within the device rating. The zener diode may fail short if the rating is exceeded. Since it does not degrade with use, it is often used where spikes are more frequent.

Selenium Voltage Suppressor: It is used to limit voltage spikes mostly in high-energy dc circuits such as in the exciter field of an ac generator. It can absorb high energy, but does not clamp well. However, it has a longer life than MOV.

Surge Suppressor Ratings

There are many rating systems that measure the surge protection:

Joule rating: It is a good parameter for gauging the surge suppressor’s ability to absorb surge energy. Since surges commonly occur for microseconds or shorter durations, the energy is typically under 100 J. A well designed surge protector does not rely on absorbing the surge energy, but more on surviving the process of redirecting it.

It fails gracefully in reverse bias to divert most of the surge energy to ground, thus sacrificing itself, to protect the equipment plugged to it. In general, 200 J rating gives basic protection and 400 J surge suppressor provides a good protection to most small computer type equipment. The ampere rating is not a measure of the surge suppressor ability to protect the load.

Clamping voltage: It specifies the voltage at which the metal oxide varistor inside the suppressor breaks down and diverts the surge to the ground. A lower clamping voltage, also known as the let-through voltage, indicates better protection, but a shorter life expectancy. The lowest three levels of protection defined in the UL rating are 330 V (suitable for most 120 V ac loads), 400 V, and 500 V.

Noise filter: Most surge suppressors also include high frequency special EMI suppressor (electrical noise filter). The EMI suppression is stated as decibel level (Db) at a specific frequency (kHz or MHz). The higher Db rating provides greater attenuation of the incoming noise.

Response time: A short time delay of several nanoseconds exists before the MOV breaks down in reverse. However, surge voltages usually take a few microseconds to ramp up and reach their peak values. The surge suppressor with a nanosecond delay responds fast enough to suppress the most damaging portion of the spike.

Thanks for reading about “lightning and switching voltage protection methods”.

Related Posts

- Lightning Arrester Types & Working

- Lightning and Switching Voltage Protection Methods

- Personnel Protective Devices

- How Lightning Arrester Works

- Overvoltage Protection by Lightning Arresters

- Insulation coordination of Electrical Equipment

- MCCB Circuit Breakers

- Differential Protection of Generator & Alternator

- Types of Current Limiting Reactor

- Classification | Types of Protective Relays

- Fuse Selection Criteria

- Protection of Transmission lines by Ground Wires

ATSCables offers a wide range of network management solutions for your home or office. Whether you need cable organizers, patch panels, racks, shelves, or wall plates, you can find them here at affordable prices. Browse our product categories and order online today.