Biomass is an organic matter produced by plants, both grown on land (terristial biomass) and grown on water (aquatic biomass) and their derivatives and animal manure. The energy obtained from biomass is called the biomass energy.

Biomass can be considered a form of solar energy as it is used indirectly to grow these plants by photosynthesis. It is renewable source of energy because the organic matter is generated round the year.

Note that the fossil fuels like coal, petroleum products and natural gas are not considered as biomass since they are produced from dead, buried biomass under pressure and temperature during several millions of year.

Biomass Resources and their Classification

Biomass resources can be classified in the following three groups :

(i) Biomass obtained from cultivated fields, crops, forests, algae and organism living both on land and water.

(ii) Biomass derived from wastes e.g. Municipal waste, animal and human excreta, forest waste; sewage etc.

(iii) Biomass converted into liquid fuels like methanol, ethanol etc. which can be used in engines or by biomass gasification e.g. methane gas obtained from dung and agricultural wastes.

Photosynthesis Process

Biomass is produced in the photosynthesis process which coverts the solar energy into biomass energy. Photosynthesis process only occurs in green plants.

It is the process of combining the CO2 from the atmosphere with water plus light energy to produce carbohydrates (sugars, starches, celluloses etc.) and oxygen. The photosynthesis is a complex process, but the overall photosynthesis process can be represented by the following equation:

6CO2 + 6H2O + light energy –à C6H12O6 + 6O2

Availability of Biomass

Biomass includes wood waste and biogases (sugarcane refuse) which has substantial potential to generate electrical power. These are bulky and highly dispersed and contain large amounts of water (50% to 90%). Thus it is not economical to transport over long distances.

It is convenient to use this energy source at the place close to the source. However, it can be converted into liquid or gaseous fuels which can be easily transported and used away from their source of produce.

Land crop includes the following:

- Sugar crops such as sugar cane and sweet sorghum.

- Plants with soft stem which die down after flowering like herbs grass etc called herbaceous plants. These plants can be used for conversion into liquid and gaseous fuels. It is estimated that land crop is about 2 x 1012 tones having energy potential of 3 x 1018 kJ of energy.

- Forestry plants called sericulture plants.

Aquatic crops include the plants grown on fresh sea and mud water etc. e.g. algae, sea weeds etc.

In India, we have a great potential for use of biomass as an alternate source of energy. Biomass energy can be used for rural, urban and industrial applications and for power generation.

Energy Conversion from Biomass

The various processes used for conversion of biomass into energy or bio fuels can be classified as follows:

- Direct combustion

- Thermo chemical conversion

- Biochemical conversion

Direct Combustion

The direct combustion of biomass in presence of oxygen/air to produce heat and by-products is called direct combustion. The complete combustion of biomass into ash is called incineration.

This heat energy in the product gases or in the form of steam can be used for various applications like space heating or cooling, power generation, process heating in industries or any other application.

Various designs of boilers and furnaces are available to burn biomass like wood, dung, dried vegetable wastes from food industry, pulp, bagasse from sugar industry and municipal wastes etc. The moisture content in biomass and their wide range of composition tends to produce low calorific value of fuel.

However, if biomass energy by combustion is used as co-generation with conventional fuels, the utilization of biomass energy makes it an attractive proposition.

Thermo Chemical Conversion of Biomass

The thermo-chemical reactions can convert the organic biomass into more valuable and convenient form of products as gaseous and liquid fuels, residues and by-products etc. at different pressures and temperatures. These processes can be carried out in following ways:

- Gasification: Heating of biomass in presence of limited oxygen and air (deficient 02/air) is called gasification. It produces gaseous fuels like H2, CO, CH4, N2 of low calorific value.

- Pyrolysis: It is the heating of biomass in a closed vessel at temperatures in the range of 500° C — 900° C in absence of 02/air or with steam. It produces solid, liquids and gases. The pyrolysis process can use all type of organic materials including plastic and rubbers.

The gases produced by this process include the mixture of CO, CH4, N2, H2, CO2 and other hydrocarbons. The liquids produced are oil like materials (acetic acid, methanol, oil and tar) and solids produced are similar to pure carbon charcoal.

Biochemical Conversion of Biomass

The process of biochemical conversion of biomass makes use of metabolic action of microbial organism on biomass to produce liquid and gaseous fuels. These processes are of two types.

- Fermentation of biomass

- Anaerobic digestion of biomass

Fermentation : Fermentation is a process of decomposition of complex molecules of organic compound under the influence of micro-organism (ferment) such as yeast, bacteria, enzymes etc.

The examples of fermentation process is the conversion of grains and sugar crops into ethanol and CO2 in presence of yeast. 10% of ethanol so produced can be blended with petrol to produce gasohol.

The fermentation process of sugar is carried out at about 30° C in acidic conditions of ph value 4 to 5 and the completion of fermentation process takes about 50 hours.

Anaerobic digestion of biomass: The anaerobic digestion or anaerobic fermentation process involves the conversion of decaying wet biomass and animal wastes into biogas through decomposition process by the action of anaerobic bacteria.

The anaerobic bacteria is a micro-organism that can live and grow in absence of 02 or air. The biogas production in anaerobic digestion depends on the type of biomass used, temperatures, ph value of mixture etc.

For example the production of biogas from human and animal wastes takes about 10 days at optimum temperature of 35° C while the decomposition of biomass like sewage sludge, green plants etc. takes longer time. The gas produced is mixture of methane (55% to 70%) and remainder is CO2 with other impurities.

The most useful biomass for production of biogas are animal and human waste, algae, hyacinth, plant residue and other organic waste materials with high moisture content.

Biogas Generation Process

Biogas is produced by anaerobic decomposition of organic wastes by suitable bacteria. It contains (55 – 65) percent methane, (30 – 40) percent carbon dioxide and the remainder are impurities like H2S, H2, N2 gases.

The main source of production of biogas are crop residue, wet cow dung, vegetable wastes, water hyacinth, algae, poultry or piggery droppings, human waste, bagasse, rice-husk etc. Any organic material of animal or plant which is easily bio-degradable can be the source of biogas production.

Cattle dung can produce 0.037 m3 of biogas per kg of cow dung. The calorific value of gas is 21000 to 23000 kJ/kg or about 38000 kJ/m3 of gas. The material from which biogas is produced retains its value as fertilizer or as animal feed which can be used after certain processing. Biogas can he produced by digestion pyrolysis or hydrogasification.

Digestion pyrolysis is a biological process that occurs in absence of 02 and in presence of anaerobic organisms at atmospheric pressures and temperatures of 35°C — 70°C. The container in which the digestion takes place is called digester.

Bacteria used for production of biogas can be divided into two major groups based on their oxygen requirements to grow. The bacteria which grows in presence of oxygen is called aerobic bacteria and the other which grows in the absence of oxygen is called anaerobic bacteria.

When organic matter undergoes fermentation, the anaerobe bacteria extracts oxygen by decomposing the biomass at low temperatures upto 65° C in the presence of moisture. (80% to 95%), the gas so produced is called biogas.

Principles of Biogas Production from Waste Biomass

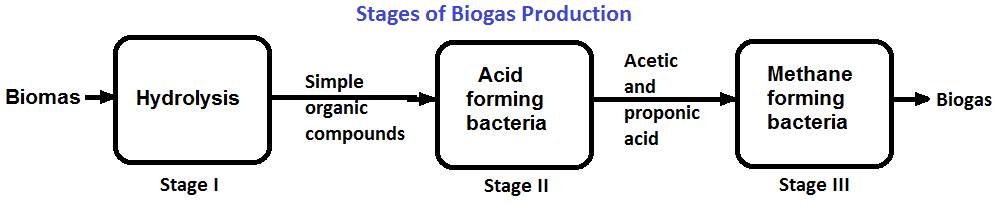

As discussed above, the biogas production from waste biomass is achieved by the action of anaerobic bacteria in presence of moisture and in the absence of oxygen. The conversion process is called biodigestion or anaerobic fermentation. The bio-chemical process takes place in three stages as shown in Figure.

These are as follows:

- Stage I – Hydrolysis: Firstly the biomass having complex compounds such as fats, proteins carbohydrates etc are broken down into simple water soluble organic compounds through the influence of water called hydrolysis.

- Stage II (Acid formation): The micro-organism of anaerobic and facultative group (which grows in absence of 02) called acid forming bacteria produce mainly the acetic acid and propoinic acid at low temperature of about 25°C with release of CO2.

In certain cases, the acid may be produced in such large quantities that all the biological activity is arrested. Thus, it becomes necessary to control the pH value of mixture.

- Stage III (Methane formation): In this stage the anaerobic bacteria called as methane, formers converts the organic acids formed in stage II into biogas having its main constituent’s as methane and CO2 with other small traces of H2S, H2 and N2 etc.

These methane formers are sensitive to pH changes. The biogas production depends on the environment maintained in the digester. The advantages of biogas production are:

(i) Waste material available after digestion and after processing can be used as fertilizer or as animal feed or fuel after drying.

(ii) The biogas after removal of CO2 produces an excellent fuel as CH4 gas. It can be used for cooking, lighting, running diesel engines, fuel for furnaces etc.

(iii) Sewage waste after biogas production is converted into less offensive slurry and almost free from pathogens (diseases producing bacteria).

(iv) Gas production is cheap.

Factors Affecting the Production of Biogas

The rate of production of biogas depends on the following factors:

(i) Temperature and pressure: The process of anaerobic fermentation and methane forming bacteria works best in the temperature range of 25°C – 55°C and pressure of about (1.1 – 1.2) bar absolute.

The rate of gas production increases with the increase in temperature but the percentage of methane reduces. It is found that temperatures 35°C – 38°C are best for methane production.

If the temperatures are lower than 20°C (as in case of cold countries and in winters) the rate of gas production falls sharply and it almost ceases at about 10°C. Thus, in cold climates, it is necessary to heat the digester to about 35°C.

(ii) Solid concentration and loading rate: The cow dung, water and various organic residues from agricultural waste are supplied as feed to the digester. The proportions recommended are:

Cow dung + solid waste 1:1 by weight and forming to about 10% of solid content and 90% of water.

The amount of feed supply per day to the digester is called loading rate. It is dependent on the size of the plant. The recommended loading rate is about 0.2 kg/m3 of digester capacity. The underloading and overloading reduces the biogas production. The loading of feed must be carried out every day at the same time so as to keep the solid concentration ratio constant in the digester.

(iii) Retention period: It represents the time period for which the fermentable material remains inside the digester. This period ranges from 35 days to 50 days depending upon the climatic conditions and location of the digester. The longer retention period needs larger size digester and it allows more complete digestion of feed.

(iv) pH value or Hydrogen ion concentration: pH value indicates the degree of acidity or alkalinity of a solution. The pH value is represented as the logarithm of the reciprocal of hydrogen ion concentration in gm equivalent per liter of solution. pH value in the range 0 – 7 represents acidic solution and in the range 7-14 indicates the alkaline solution.

In the initial stages of acid forming stage of digestion, the pH value may be around 6 cr less, however during methane formation stage the pH value higher than 7 is maintained since methane formers are sensitive to acidity.

For above reasons the optimum pH value of digester solution between 7 to 8 is recommended for biogas formation.

(v) Nutrients concentration: The major nutrients required by the bacteria in the digester are N2, P, S, C, H2, 02 to accelerate the anaerobic digestion rate. Thus it is necessary that the major nutrients are supplied in correct chemical form and concentrations.

The carbon in carbohydrates supplies the energy and the nitrogen in proteins is needed for building of growth of bacteria. C : N ratio need to be supplied in the ratio of 30 : 1 with 2% phosphorous for maximum biological activity.

Thus, for accelerated fermentation and production of biogas nutrients like C, P, N2 are needed. Oil cakes and animal urine are found to be suitable nutrients for this purpose.

(vi) Toxic substances: The presence of ammonia, pesticides, detergents, heavy metals are considered as toxic substance to micro-organisms since their presence reduces the fermentation rate. Also the digested slurry if allowed to remain in digester beyond certain time, it becomes toxic to micro-organism growth.

(vii) Digester size and shape: It is found that the biogas production per unit volume of digester is high when its diameter to depth ratio ranges between 0.66 to 1.

(viii) Stirring or agitation of the content of digester: Since bacteria in the digester has very limited reach to their food, it is necessary that the slurry is properly mixed and bacteria get their food supply.

It is found that occasional mixing allows the masses that float at the top in the form of scum allows to mix with the deposits at the bottom. It helps in improving the fermentation process.

Thanks for reading about “biomass renewable energy.