Hi friends,

In this article, I am discussing the construction of dc motor and hoping you will find it useful.

Both the DC machines i.e. DC generator and DC motor have the same construction. Therefore, either machine can be used as a motor or a generator. So the following discussion about the construction of DC motor is equally valid for the construction of the DC generator. Also, we can entitle it as the construction of DC machine.

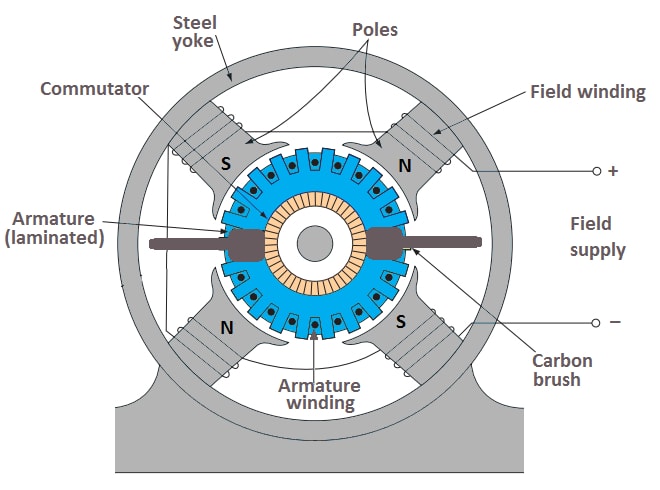

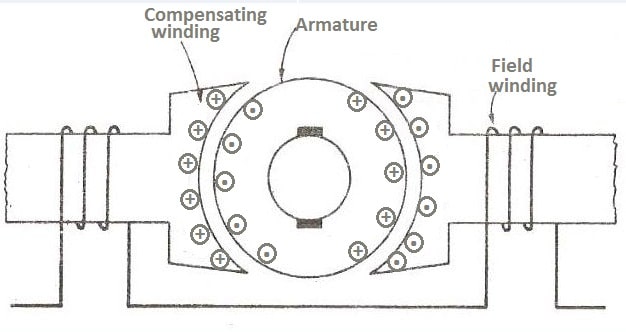

A DC motor or machine consists of two windings namely field winding and armature winding. The field winding is stationary and the armature winding can rotate.

The field winding produces a magnetic flux in the air gap between the armature and field windings and the armature is placed in this magnetic field. The construction of DC motor or machine is shown in the following Figure.

Parts Used in Construction of DC Motor | Machine

The main parts used in the construction of DC motor are the yoke, poles, field winding, commutator, carbon brushes bearings, etc. A brief description of the various parts is as follows:

Yoke

The yoke acts as the outer cover of a DC motor and it is also known as the frame. The yoke is an iron body, made up of low reluctance magnetic material such as cast iron, silicon steel, rolled steel, etc.

Yoke serves two purposes, firstly it provides mechanical protection to the outer parts of the machine secondly it provides a low reluctance path for the magnetic flux.

Poles and Pole Shoe

The pole and pole shoe are fixed on the yoke by bolts. These are made of thin cast steel or wrought iron laminations that are riveted together. Poles produce the magnetic flux when the field winding is excited.

A Pole shoe is an extended part of a pole. Due to its shape, the pole area is enlarged and more flux can pass through the air gap to the armature.

Field Winding

The coils around the poles are known as field (or exciting) coils and are connected in series to form the field winding. Copper wire is used for the construction of field coils. When the DC is passed through the field windings, it magnetizes poles that produce magnetic flux.

The connection of the field winding and the armature winding is done according to the type of the motor and decides the characteristics of the motor.

Armature Core

It is a cylindrical drum and keyed to the rotating shaft. A large number of slots are made all over its periphery, which accommodates the armature winding. Low reluctance, high permeability material such as silicon steel is used for armature core.

The laminated construction is used to produce the armature core to minimize the eddy current losses. The air holes are also provided on the armature core for the air circulation which helps in cooling the motor.

Armature Winding

The armature winding plays a very important role in the construction of a DC motor because the conversion of power takes place in the armature winding. Based on connections, there are two types of armature windings named:

- Wave Winding

- Lap Winding

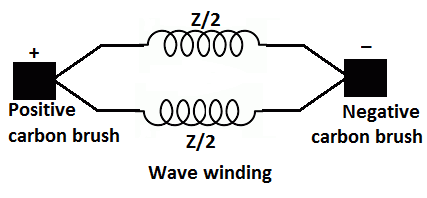

Wave Winding: In wave winding, all the armature coils are connected in series through commutator segments in such a way that the whole armature winding is divided into two parallel paths.

If there are Z conductors in the armature then there will be 2 parallel paths each containing Z/2 conductors in series. The wave winding is useful for high voltage low current motors.

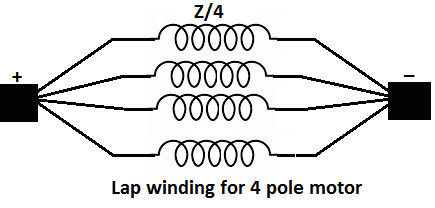

Lap Winding: In lap winding the armature conductors are divided into the groups equal to the number of poles of the motor. All the conductors in each group are connected in series and all such groups are connected in parallel. Therefore, in lap winding the number of parallel paths (A) is equal to the number of poles (P).

If there are Z conductors in the armature and 4 poles then there will be 4 parallel paths each containing Z/4 conductors in series.

Due to the existence of a large number of parallel paths, the lap wound armature is capable of supplying larger load currents. Therefore, lap winding is used for low voltage high current DC motors.

Commutator

It is mounted on the shaft. It is made up of a large number of wedge-shaped segments of hard drawn copper, insulated from each other by a thin layer of mica.

The commutator connects the rotating armature conductor to the stationary external circuit through carbon brushes. It converts alternating torque into unidirectional torque produced in the armature.

Carbon Brushes

The current is conducted from the voltage source to the armature by the carbon brushes which are held against the surface of the commutator by springs. They are made of high-grade carbon steel and are rectangular.

Bearings

The ball or roller bearings are fitted in the end housings. The friction between stationary and rotating parts of the motor is reduced by bearing. Mostly high carbon steel is used for making the bearings as it is a very hard material.

Interpoles

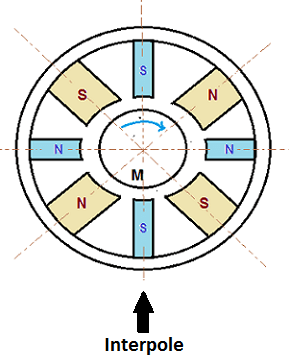

It has seen that the brushes on the commutator short-circuit the armature coils when they are slipping from one commutator segment to the next. At this instant, EMF induced in those particular coils should be zero otherwise this EMF will create sparking on the commutator due to short-circuit. This is achieved by placing the carbon brushes at the MNA. (MNA is defined as the axis at the right angle to the main flux where armature conductors do not have any EMF in them.

At no-load, the motor takes very low current and therefore, the flux produced by the armature remains very weak. However, when the motor is loaded, the flux produced by the armature increases due to an increased amount of the armature current. This weakens and distorts the main magnetic field (i.e. magnetic field produced by poles). This effect of armature flux on the main magnetic field is known as armature reaction.

This armature reaction shifts the MNA, and sparking starts on the commutator. However, we can eliminate this sparking by shifting the position of carbon brushes to the new MNA. But it is practical for only almost constant loads. When a load is very fluctuating in nature, this method becomes very difficult to execute.

To counter the effect of armature reaction, usually, interpoles are used. These are placed mid-way between the main poles. The polarity of the interpole must be that of the main pole just behind it.

The windings of interpoles are connected in series with the armature. Thus they set up a flux equal and opposite to the armature flux and cancels the effect of armature reaction. And we no longer have to shift the brushes to eliminate the armature reaction. These are fitted on all DC motors except the smallest sizes or lowest speeds.

Compensating Winding in DC Motor

In some applications, like steel mills, rolling mills, etc. the motor has to accelerate, decelerate, stop, reverse all in a matter of seconds. Therefore, in these applications, the armature current increase, decrease and reverse very frequently. It causes very sudden changes in armature reaction. In such cases, the interpoles are not sufficient to cure the armature reaction.

To eliminate the armature reaction in such applications, additional compensating windings are used. A compensating winding is an auxiliary winding embedded in slots in the pole faces of main poles.

It is connected in series with the armature in a manner so that the direction of current through the compensating conductors in any pole face will be opposite to the direction of current through the adjacent armature conductors as shown in Figure. It produces the flux equal and opposite to the armature flux thus completely neutralize the armature reaction.

Since the addition of compensating winding increases the cost of the motor considerably used only for machines designed for unusual severe service.

Thanks for reading about the construction of dc motor. If you have any questions then you can ask me in the comment section given below. For more details, you may visit Wikipedia.

Thanks for sharing such an informative article.if you’re looking hydraulic equipment and tools in dammam saudi arabia,Star Namu Trading as a leading company in importing and supplying the pneumatic and hydraulic components to various manufacturing industries to keep the operations of machines running efficiently today to continuously improving and optimizing for a more productive tomorrow. Our dedication and hard work for our clients have helped us to grow and become a premier supplier of pneumatic and hydraulic controls, equipment, and systems that we are today.Our products are generally used in all types of manufacturing industries where huge machinery are used for their productions including Plastic Industry, Paper Industry, Agriculture Industry, Mining Industry, Oil & Gas Industry, Chemical & PetroChemical industry, Cement Industry, Construction Industry, Food & Beverages Industry, Ceramic Industry, Steel Industry, Power Plant Industry, Edible Oil Industry, Pharma Industry, and many other general Industrial Sector

What a deep knowledge about motors, Great !!!