Hi friends,

In this article, I am going to discuss the thermocouple working principle, its types and properties.

Thermocouples are the temperature sensors which are extensively used for the measurement of the temperature variations. They sense the temperature and the temperature is further measured by other instruments after sensing it.

As they convert a non-electrical quantity (temperature) into voltage (electrical quantity) so they are transducers also. Since the do not require any external power source to operate, so they are active transducers.

Thermocouple Working Principle

The thermocouple working principle is based on the Seeback Effect. This effect states that when a closed circuit is formed by jointing two dissimilar metals at two junctions, and junctions are maintained at different temperatures then an electromotive force (e.m.f.) is induced in this closed circuit.

The amount of induced e.m.f. is different for different metal combinations and is proportional to the temperature difference of the junctions. This is the basic thermocouple working principle.

Thermocouple Working

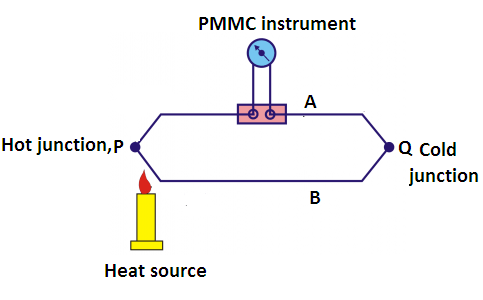

A typical circuit diagram of a thermocouple is shown in Figure. In the Figure, two dissimilar metals ‘A’ and ‘B’ are joined at the two junctions ‘P’ and ‘Q’. Here the ‘P’ junction is measuring junction or hot junction whereas the junction ‘Q’ is the reference junction or cold junction. And a PMMC instrument is connected in this arrangement as shown in Figure.

When these junctions are kept at different temperatures, generally cold junction is kept at 0oC and measuring junction is kept at an unknown temperature which we want to measure (i.e. the temperature of the junction is raised by heating it). An e.m.f. will be generated in this circuit due to the temperature difference of the junctions.

This e.m.f. is in the order of millivolts. And the e.m.f. can be measured with the help of a PMMC instrument by connecting it in the circuit as shown in Figure.

When both the junctions are at the same temperature, e.m.f. generated at both junctions will be the same. No current will flow through the circuit. And there will be no deflection in the meter.

When both the junctions are at different temperatures, a current will flow through the meter. And the meter will show the deflection. As the generated e.m.f. is proportional to the temperature difference, the amount of current flow will also be proportional to the temperature difference. And therefore, the meter can be calibrated directly in terms of temperature.

The reference, or cold junction is normally connected to the measuring instrument and held at 0 oC. For accurate temperature measurement, the reference junction temperature must remain constant or suitable compensation provided if it should change. To reduce inaccuracies, most thermocouples are now installed with instruments that provide automatic reference compensation.

In this way, a thermocouple is used for temperature measurement. As it is converting a non-electrical quantity (temperature) into an electrical quantity (e.m.f.) it can also be used as a transducer. Since it does not require any power source to operate, it is a secondary transducer.

These are used to measure the temperature up to 1400oC. There are different combinations of metals which are used in thermocouples. Different combinations generate different e.m.f.s.

The metals for the construction of a thermocouple should be chosen so that we can get a linear relationship between change in temperature and generated e.m.f.

Choice of metal also depends on the temperature range to be measured and on the nature of the atmosphere in which the thermocouple is to be used.

The e.m.f. generated in a thermocouple is given by:

E = a(∆θ) + b(∆θ)2

∆θ = difference in temperature between two junctions (in oC)

a, b = constants

generally, ‘a’ is very large as compare to ‘b’ so ‘b’ can be neglected. Therefore, the above expression can be approximated as under:

E = a(∆θ)

∆θ = E/a

Generally, these are not installed in pipelines or equipment directly. They are usually installed in protective wells so that can be replaced or removed easily without shut down of the plant.

With the introduction of protective wells, the response of a thermocouple slows down considerably. Where the fast response is a primary requirement, bare or thin sheathed thermocouples should be used.

Types of Thermocouple

T – Type Thermocouple

Positive wire — Cu

Negative wire — Constantan

It can be used up to 350oC. It is very stable and inexpensive. Generally, it is used for very low-temperature applications.

E – Type Thermocouple

Positive wire — Chromel

Negative wire — Constantan

It can be used up to 850oC. It is most sensitive thermocouple. It generates a high output voltage.

J – Type Thermocouple

Positive wire — Iron

Negative wire — Constantan

It can be used up to 1000 oC. It is a very common type of thermocouple. Its stability is high.

K — Type Thermocouple

Positive wire — Chromel

Negative wire — Alumel

It can be used up to 1200oC. It is a widely used type of thermocouple. It is a cheaper type as compared to other types.

S – Type Thermocouple

Positive wire — Platinum 10% Rohodium

Negative wire — Platinum

It can be used up to 1400oC. It has very high precision thus used for very high accuracy requirements.

The current will flow from + ve marked lead to the – ve marked lead. In thermocouples, negative lead is generally a red colored wire. The color of positive lead will be according to its type.

Advantages:

- They follow the temperature changes with a small time-lag. So it can be used in the applications where very rapid changes in temperature take places. It responds to those changes very quickly.

- These are very convenient for measuring the temperature at one particular point in any apparatus or setup.

Disadvantages:

- They have very low accuracy. So they cannot be used for very high precision measurement.

- They have to protect against contamination to ensure long life.

- They are placed at a very large distance from the measuring device. This increases errors in the result.

Thanks for reading about “working principle of thermocouple”.

Related Posts

- Thermocouple Working Principle

- Absolute Seebeck Effect

- Basic Thermocouple Circuits

- Extensions of Thermocouple

- Functional Model of Thermoelectric Circuits

- T/X Sketch of Dual-Reference Junction Circuit

- Applications of Functional Model

- Characteristics of Thermocouples

- Thermocouple Hardware

- Thermocouple Junction Styles

- Active Tests of Thermocouple

- Calibration of Thermocouples

- Thermocouple Thermometry Practice

- Distinctive Thermocouple Noise Problems

© www.yourelectricalguide.com/ thermocouple working principle.