Induction machines are also called asynchronous machines i.e. the machines which never run at a synchronous speed. Whenever we say induction machine we mean to say induction motor. Induction motors may be single-phase or three-phase. In this article, I am discussing about three phase induction motor construction.

The three-phase induction motors are the most commonly used AC motors in the industry because they have simple and rugged construction, low cost, high efficiency, reasonably good power factor, self-starting torque and require little maintenance. Almost more than 90% of the mechanical power used in industry is provided by three-phase induction motors.

Three Phase Induction Motor Construction

Construction wise three phase induction motor has two main parts namely stator and rotor.

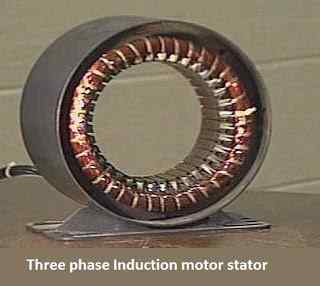

Construction of Stator

It is the stationary part of the motor. It has three main parts, namely;

- Outer frame

- Stator core

- Stator winding

Outer frame

It is the outer body of the three phase induction motor. Its functions are to support the stator core and winding and to protect the inner parts of the machine. For small machines, the frame is casted but for large machines, it is fabricated. The end shields, which also carry the bearings, are bolted to the outer frame. To place the motor on foundation feet are provided in the outer frame.

Stator core

The stator core is to carry the alternating magnetic field which produces hysteresis losses and eddy current losses, therefore, the core is built up of high-grade silicon steel stampings.

The stampings are assembled to the stator frame under hydraulic pressure. Each stamping is insulated from the other with varnish layer. The thickness of the stamping usually varies from 0.3 to 0.5 mm. Slots are punched on the inner periphery of the stampings, as to accommodate stator winding.

Stator winding

The stator core carries a three-phase winding which is usually supplied from a three-phase supply system. The six terminals of the winding (two of each phase) are connected in the terminal box of the machine.

The stator of the motor is wound for a definite number of poles, the exact number being determined by the requirement of speed. It will be seen that greater the number of poles, the lower the speed and vice-versa, since Ns α 1/P.

The three-phase winding may be connected in star or delta externally. The windings are designed to be delta connected for normal running.

Construction of Rotor

It is the rotating part of the three phase induction motor. There are two types of rotors, which are employed in the induction motors.

- Squirrel cage rotor.

- Phase wound rotor.

Construction of Squirrel Cage Rotor

The motor employing this type of rotors are known as squirrel cage induction motors. Most of the induction motors are of this type because of simple and rugged construction of rotor. A squirrel cage rotor consists of a laminated cylindrical core having semi-closed circular slots at the outer periphery. Copper or aluminum bar conductors are placed in these slots and joined at each end by copper or aluminum rings, called short circuiting rings.

Thus, the rotor winding is permanently short circuited and it is not possible to add any external resistance in the rotor circuit.

The rotor slots are usually not parallel to the shaft but are skewed which;

- reduces humming thus ensuring the quiet running of a motor,

- results in smoother torque curves for different positions of the rotor,

- reduces the magnetic locking of the stator and rotor,

- increases the rotor resistance due to the increased length of the rotor bar conductors.

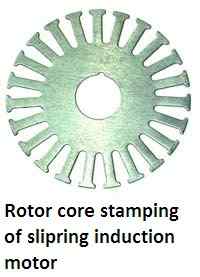

Construction of Phase Wound Rotor

A phase wound rotor of three phase induction motor is also called slip ring rotor and the motors employing this type of rotor are known as phase wound or slip ring induction motors. Slip ring rotor consists of a laminated cylindrical core having semi-closed slots at the outer periphery and carries a 3-phase insulated winding.

The rotor is wound for the same number of poles as that of the stator. The three finish terminals are connected together and the three start terminals are connected to three copper slip rings fixed on the shaft. In this case depending upon the requirement, any external resistance can be added in the rotor circuit. In this case also the rotor is skewed.

Three Phase Induction Motor | All Posts

- Three Phase Induction Motor Construction

- Rotating Magnetic Field in Three Phase Induction Motor

- Three Phase Induction Motor Working Principle

- Induction Motor Slip

- Torque Formula for Induction Motor

- Torque Slip Characteristics of Induction Motor

- Losses in Induction Motor

- Induction Motor Tests

- Starting Methods of Induction Motor

- Double Squirrel Cage Induction Motor

- Speed Control of 3 Phase Induction Motor

- What is a variable frequency drive?

- Autotransformer Starter Working Principle

- Thermal Overload Relay Working

- Induction Motor Equivalent Circuit

- Linear Induction Motor Working | Applications

© https://www.yourelectricalguide.com/ three phase induction motor construction.